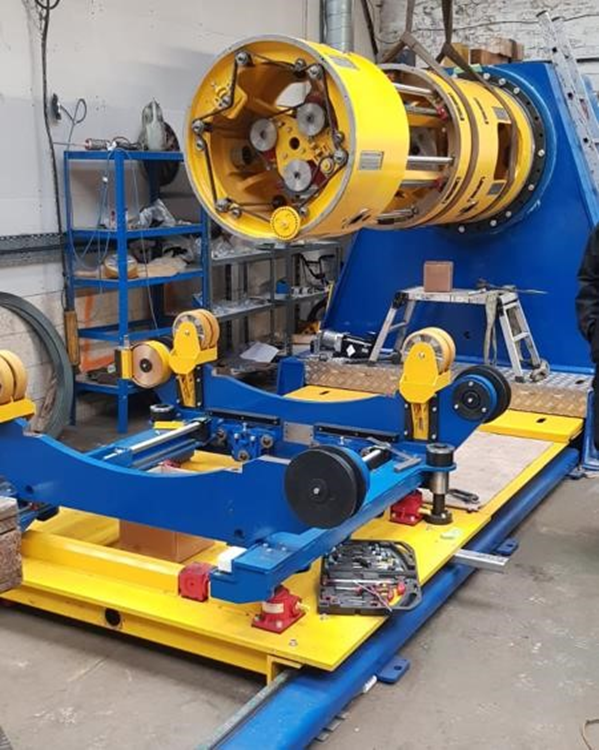

Scanner

A recent job included the full machining, fabrication, painting, and assembly of a highquality scanner for the rail industry. The fully finished product is responsible for identifying and locating defects in a train to prevent failure of key components. It consists of numerous mild steel parts which were individually fabricated and assembled via a series of high strength welds. All the welds were non-destructively tested in order to conform to BSEN 1090 – class 2. This project is a great example of the precision and quality that goes into the bespoke steel fabrication here at FEM.